Application examples

Automatic cleaning of oxygen sensors means comfortable and no-service operation during measuring oxygen in an arbitrary location and for any water quality. There is no problem with slime, fibre substances and other impurities.

|

Oxygen sensor without automatic cleaning in aeration tank with water containing slime micro organisms after 1 week exposition without manual cleaning.

|

Oxygen sensor with automatic cleaning in aeration tank with water containing slime micro organisms after 12 months exposition without any manual cleaning.

Biological wastewater treatment plants

The measurement of concentrations of oxygen dissolved in water is utilised mainly for monitoring and controlling the activation and nitrifying processes. A suitable oxygen concentration enables to minimise the energy consumption of aeration facilities and, at the same time, to ensure the optimal operation of activation (nitrifying) and de-nitrifying stages during continuously changing operation conditions. Therefore, it is possible to remove organic pollutants as well as nitrogenous substances in a very effective way – with minimal electricity consumption, which is one of the most costly items during operation of a wastewater treatment plant.

The measurement of concentrations of oxygen dissolved in water is utilised mainly for monitoring and controlling the activation and nitrifying processes. A suitable oxygen concentration enables to minimise the energy consumption of aeration facilities and, at the same time, to ensure the optimal operation of activation (nitrifying) and de-nitrifying stages during continuously changing operation conditions. Therefore, it is possible to remove organic pollutants as well as nitrogenous substances in a very effective way – with minimal electricity consumption, which is one of the most costly items during operation of a wastewater treatment plant.

The INSA systems for measuring oxygen concentrations operate in a reliable way in hundreds of both municipal wastewater treatment plants and water treatment  plants located at food production plants, tanneries, pharmaceutical facilities, rendering plants etc. The measuring instruments are always connected to frequency converters or automatics controlling the output of aeration facilities. Frequency converters may be directly controlled by controllers no extra apparatuses are necessary.

plants located at food production plants, tanneries, pharmaceutical facilities, rendering plants etc. The measuring instruments are always connected to frequency converters or automatics controlling the output of aeration facilities. Frequency converters may be directly controlled by controllers no extra apparatuses are necessary.

The measurement of concentrations of oxygen in water treatment plants is very demanding – especially in cases when slime is created on the surface of oxygen sensors and maintenance workers have to clean the sensors even once a day (in extreme cases). Automatic cleaning (the SPO 41MEK sensor) is an ideal solution for these cases – manual cleaning is not necessary any more. Automatic cleaning results in safer operation of water treatment plants. It also means more comfort for operators or maintenance workers even in cases when slime is not created on the sensors and the sensor is more or less cleaned with the movement of the measured water.

Sludge-management regeneration tanks are among other sewage treatment places where the monitoring of the oxygen concentration is important. Even here, the contamination of sensor surfaces is a major problem during measuring.

The measurement of oxygen is also important in reservoirs of final-purification. The measuring process there is performed at the minimal speed of water flow – when the electrochemical oxygen sensors cannot work without additional mixing optical sensors work perfectly. Unlike the situation in the activation tanks of wastewater treatment plants, the small speed of the water flow makes the self-purifying of sensors impossible; therefore it is impossible to measure without automatic cleaning. Even in these cases, the INSA systems with automatic cleaning function absolutely perfectly.

Drinking water treatment plants

The measurement of oxygen is also important in drinking water treatment plants that process surface water. Changes in oxygen concentrations “inform” about changes in organic overload and may signalise that manganese is released into the untreated water. The level of an oxygen concentration in raw (untreated) water also influences the operating mode of the particular technological stages of a water treatment plant.

Surface water monitoring

The level of an oxygen concentration is important information on surface water pollution. The concentration of oxygen in clean surface water is usually between 85% - 95% of saturation. During the circadian cycle, oxygen concentrations change due to alternations of intensity of photosynthesis. The dynamics of changes are significantly higher in heavily eutroficated water.

The level of an oxygen concentration is important information on surface water pollution. The concentration of oxygen in clean surface water is usually between 85% - 95% of saturation. During the circadian cycle, oxygen concentrations change due to alternations of intensity of photosynthesis. The dynamics of changes are significantly higher in heavily eutroficated water.

As each monitoring station includes the measurement of oxygen concentration, it is very convenient to use sensors with automatic cleaning of the SPR 41ME type or the SPO 41MEK type respectively, which enable long-term and no-service operation of a monitoring station.

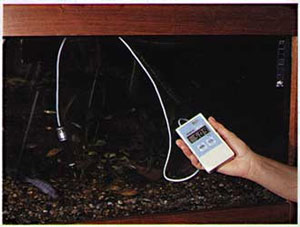

Fish farming

The information on the amount of oxygen in water of fish nurseries, fish storage ponds and fish rearing ponds is vitally important for fish producers. The lowest concentration level is considered at the level of 3 - 4 mg per litre, depending on the sensitivity of the fish population. Salmonid fish requires a concentration at the level of 6 mg per litre.

The information on the amount of oxygen in water of fish nurseries, fish storage ponds and fish rearing ponds is vitally important for fish producers. The lowest concentration level is considered at the level of 3 - 4 mg per litre, depending on the sensitivity of the fish population. Salmonid fish requires a concentration at the level of 6 mg per litre.