Application examples

Drinking water treatment plants

Suitable flocculants are partitioned into the feed-in technological units in order that organic substances are removed from raw (untreated) water. The size of the doses depends on the amount of water and concentrations of organic substances. The amount of water can be simply measured with a water meter. The concentration of organic substances can be measured:

Suitable flocculants are partitioned into the feed-in technological units in order that organic substances are removed from raw (untreated) water. The size of the doses depends on the amount of water and concentrations of organic substances. The amount of water can be simply measured with a water meter. The concentration of organic substances can be measured:

- In a laboratory, which is laborious, and the result is available as late as in several hours when the situation may be absolutely different.

- By using an on-line analyser of chemical oxygen demand or of total carbon. This solution is out of option for common water treatment plants due to the required investment and operational costs.

For these cases, using an UV analyser with automatic cleaning is an ideal solution. The investment costs of this solution are a fraction of costs needed for an on-line analyser. The operational costs are practically non-existent – the UV analyser with automatic cleaning requires only re-calibration with distilled water once in a month.

|

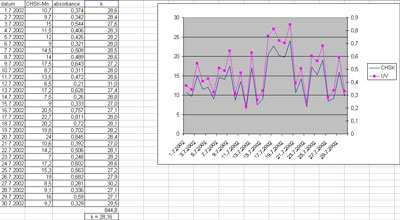

As the qualitative composition of raw (untreated) water practically does not change and as analysers are equipped with turbidity correction, the correlation between the data from an analyser and the data on chemical oxygen demand obtained from a laboratory is very high.

Analysers enable automatic optimisation of doses without laboratory tests and without the interference of operators, thus ruling out faults caused by human intervention.

In all cases, the measuring instruments work with automatic cleaning of the optical path.

Biological wastewater treatment plants

As UV analysers continuously measure the total concentration of organic substances, and, at the same time, the amount of suspended and colloidal substances (turbidity), the measuring instruments appear to be ideal control elements at the outlet of a wastewater treatment plant. The measuring instruments continuously monitor the feed water and enable to undertake prompt interventions in the technological processes in case there is an above- limit concentration in water.

As UV analysers continuously measure the total concentration of organic substances, and, at the same time, the amount of suspended and colloidal substances (turbidity), the measuring instruments appear to be ideal control elements at the outlet of a wastewater treatment plant. The measuring instruments continuously monitor the feed water and enable to undertake prompt interventions in the technological processes in case there is an above- limit concentration in water.

Analyzer APD 66 – process testing. Analyzer with automatic cleaning, measuring waste water in the drain of WWTP. Condition of the analyzer at temperature 27°C below zero.

The continuous operation is the principal advantage of these measuring instruments. The information on concentrations of organic substances is available immediately, without any delay. The measuring instruments need no extra chemicals and practically do not require any maintenance.

In all cases, the measuring instruments work with automatic cleaning of the optical path.

Extremely easy re-calibration (compensation of the zero-point drift) with distilled water is also one of the advantages of the INSA conception. It is not necessary to uninstall the detection part of a measuring instrument from the measured environment and to carry out laborious and unpleasant cleaning.

Surface water monitoring

As the UV analyser does not require the refilling of auxiliary solutions, no filtration of the measured specimen and practically no maintenance, it is an ideal measuring instrument for determining the total concentration of organic substances in automatic monitoring stations. In this case, the measuring requires automatic cleaning as well.

As the UV analyser does not require the refilling of auxiliary solutions, no filtration of the measured specimen and practically no maintenance, it is an ideal measuring instrument for determining the total concentration of organic substances in automatic monitoring stations. In this case, the measuring requires automatic cleaning as well.